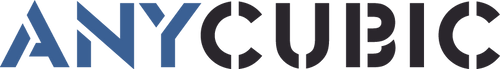

Highly Resilient & Crack Resistant

Excellent impact-resistant property, drillable, and crisp edges. With a Shore Hardness of 86D, the ABC-Like Resin 3.0 is extremely resilient against cracking, capable of withstanding drill operations without cracking or deformation. It's ideal for printing mechanical assembly parts, electronic chassis, and automobile components.

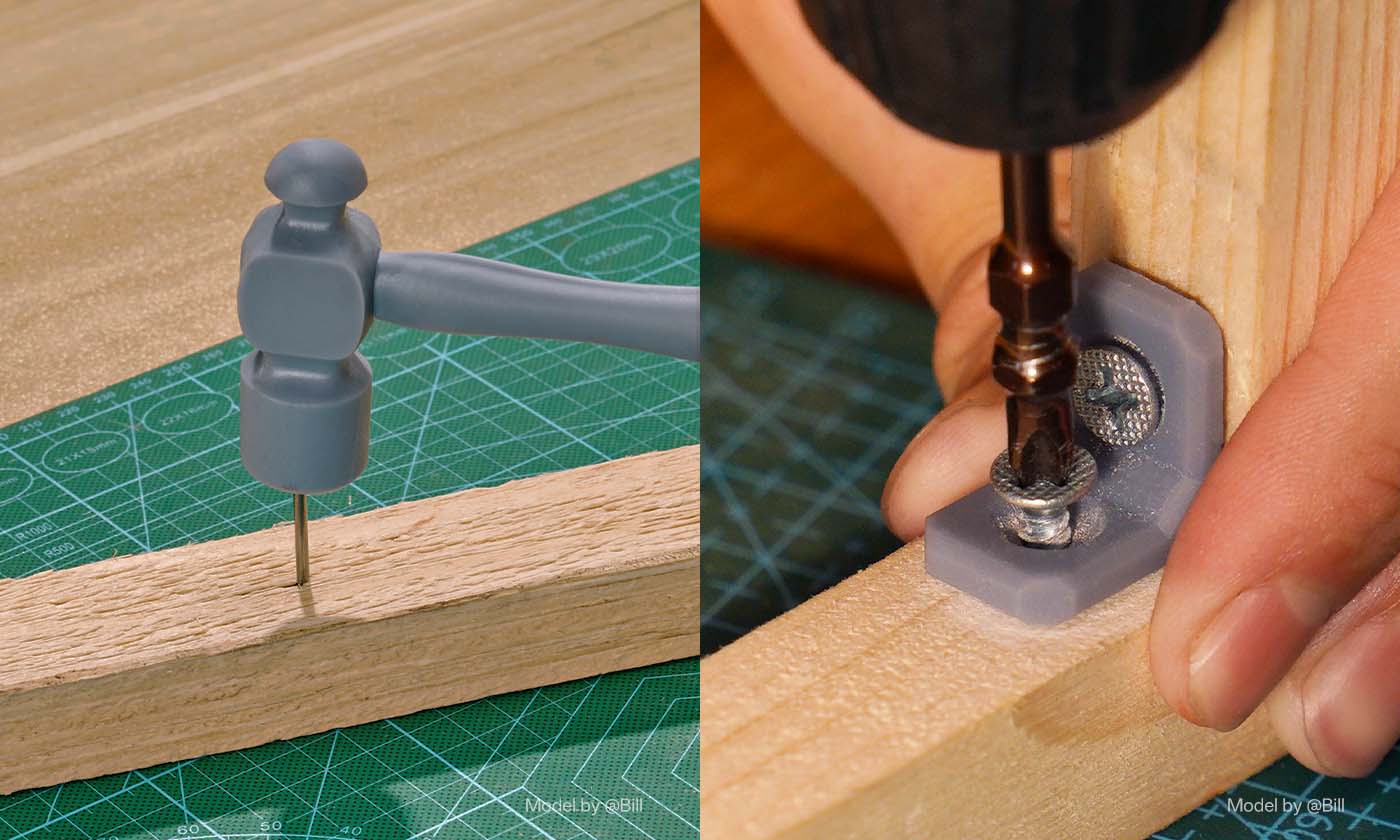

ABS-Like Resin VS ABS-Like Resin 3.0

Balanced performance, impact- & wear-resistant. Achieves an impressive 30% elongation at break, nearly double the 13% of other ABS-like resins, allowing it to withstand more stress and deformation.

Higher Accuracy with Lower Shrinkage Rate

Delivers an exceptionally high level of detail, capturing even the most intricate contours and delicate features, while ensuring a remarkably smooth texture that feels as polished as it appears—all coming together to make your prints truly come to life.

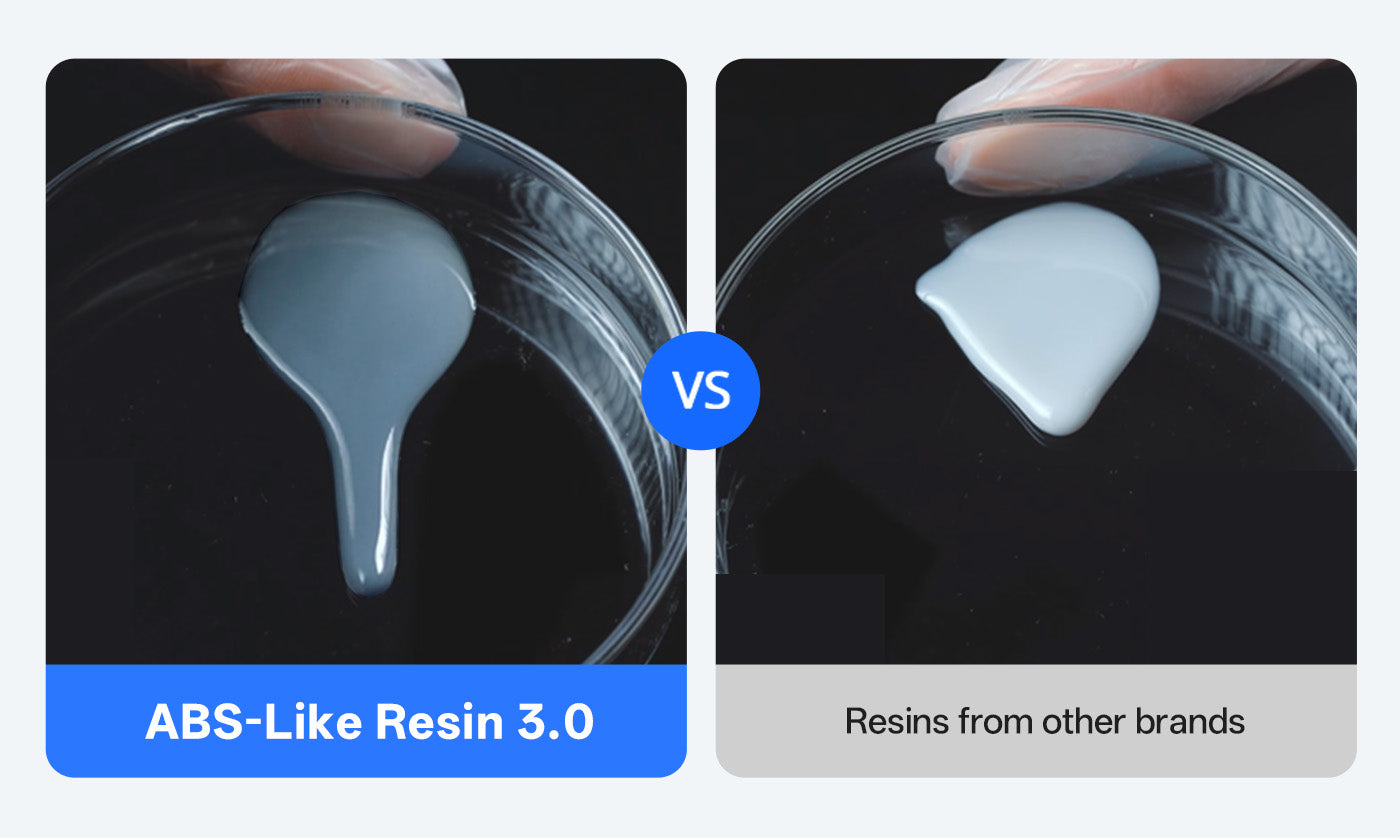

Lower Viscosity for Faster Curing

With lower viscosity and high fluidity, Anycubic ABS-Like Resin 3.0 reflows back to the print area more quickly, reducing overall print time.

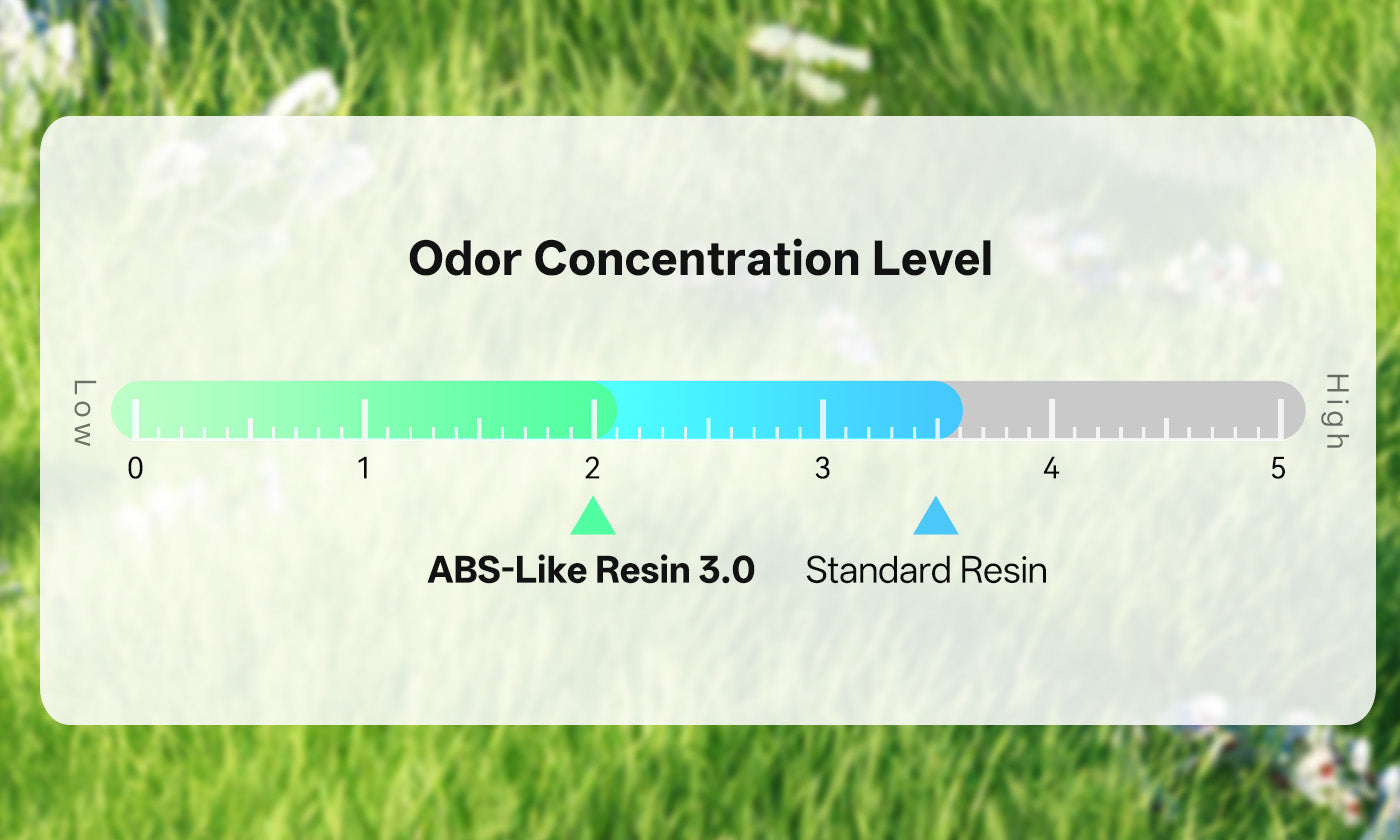

Minimal Odor & Environmentally Friendly

A fresh and more pleasant printing experience, reducing bad odor to create a cleaner, more breathable environment.

A Variety of Applications

It is compatible with a wide range of LCD and DLP 3D printers operating within the 365-405nm wavelength, offering seamless integration with most printers on the market.

Download

Resin Specification

Color Type

Recommended Printing Specification

| Printer Model | Layer Thickness | Exposure Time | Light-Off Time | Bottom Exposure Time | Bottom Layers | Anti-Aliasing Level | Z Lift Distance | Z Lift Speed | Z Retract Speed |

| Photon Mono M7 Max | 0.05 mm | 3.2 s | 0.5 s | 30 s | 5 | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M7 Pro | 0.05 mm | 2 s | 1 s | 25 s | 4 | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M7 | 0.05 mm | 2.2 s | 1 s | 35 s | 4 | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono 4 Ultra | 0.05 mm | 2.6 s | 1 s | 30 s | 5 | 1 | 5 mm | 8 mm/s | 8 mm/s |

| Photon Mono 4 | 0.05 mm | 2.8 s | 1 s | 30 s | 5 | 1 | 6 mm | 4 mm/s | 6 mm/s |

| Photon Mono M5s Pro | 0.05 mm | 3.6 s | 1 s | 30 s | 5 | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M5s | 0.05 mm | 3 s | 0.5 s | 25 s | 5 | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M5 | 0.05 mm | 2.8 s | 0.5 s | 25 s | 6 | 1 | 8 mm | 6 mm/s | 6 mm/s |

Instructions for Use

(1) Before use:

Shake the liquid resin before use. Clean the resin tank and the molding platform to keep the bottom of the resin tank in good condition for light transmission.

(2) When using:

Unscrew the cap and add it to the resin tank according to the equipment requirements. Select the correct print parameters and settings for printing.

(3) After use:

After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol(≥95%), lactate, or isopropyl alcohol cleaning solution;

(4) Post-processing steps:

A. Remove the printed model from the molding platform with a blade.

B. Submerge the model in the cleaning solution, rinse or ultrasonically wash, then take out and drain; ANYCUBlC Wash and Cure machines are suggested to ensure better effect.

C. Proper processing, such as removing support, polishing, coloring, etc.

Precautions

- The ideal condition for storing uncured resin is a cool, dark place at room temperature and protected from light to avoid high temperature or sunlight.

- Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect; thus, the resin can be properly preheated before use (not more than 60°C).

- If the resin pigment settles, it can be used after stirring or shaking.

- In order to ensure the performance of the resin, please take out the model in time after cleaning to avoid the model soaking in water for a long time.

- To ensure the mechanical properties of the model, please perform post-curing in time after cleaning and drying.

- To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing. Therefore, the following steps are recommended:

(1) The intensity of the mercury lamp or LED light source is 5-10 mW/m², and the duration is no more than 1 hour (self-regulation);

(2)The exposure time in the sun (summer) is around 1 hour;

(3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited.

(4) It is recommended to print in a dark room or be covered with a lid while printing, as resin is a photosensitive material.